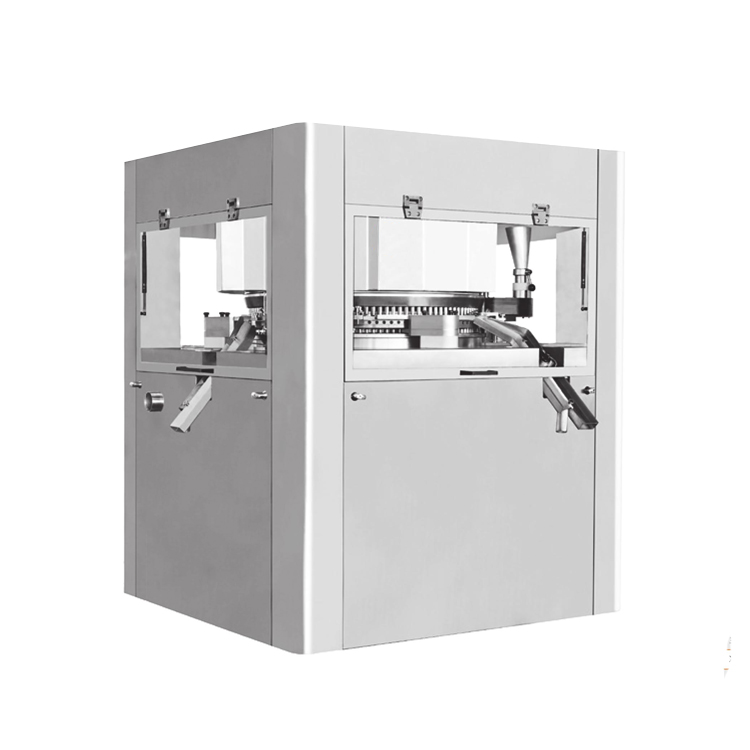

Pharmaceutical Tablet Press Machine

- TP

- China

- 40 days

- 20 sets/month

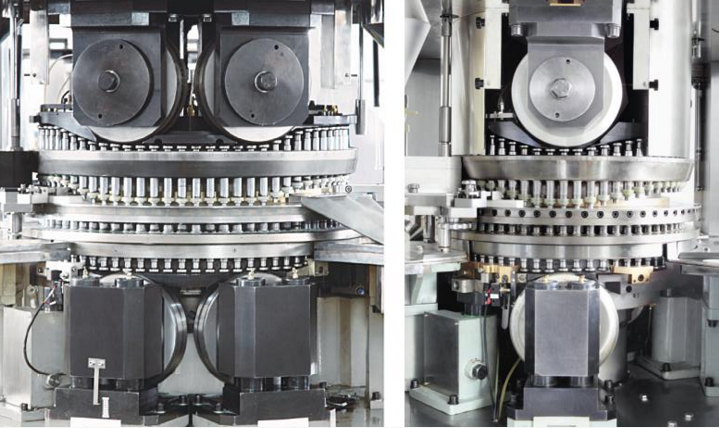

This turret removable tablet press has three groups of rollers of the same size. Each group of roller can reach 100KN pressure, which triple the pressure time for each tablets. This 3-roller design provides a new soltuion for pressing two layers of tablets.

The powder can be pressed directly without granulation, which saves much money and time. The machine is designed according to GMP standard. And this pharmacutical tablet press machine can press two colors of tablets.

The rotation turret of tablet pill press machine can be exchanged more quickly, and the cleaning and maintenance time is greatly decreased, and can help to save much labor cost and time.

Tech Data of this bi-layer tablet making machine:

Model | GZP-41 | GZP-51 | GZP-61 |

Stations | 41 | 51 | 61 |

Tooling types | D | B | BB |

Die diameter(mm) | 38.1 | 30.16 | 24 |

Punch rod diameter(mm) | 25.35 | 19 | 19 |

Turret rotation speed/R.P.M | 9~90 | ||

Max capacity(pcs/hr) | 221400 | 275400 | 329400 |

Minimum capacity | 22140 | 27540 | 32940 |

Motor power(KW) | 11 | ||

Pressure 1 (KN) | 100 | ||

Pressure 2(KN) | 100 | ||

Pressure 3(KN) | 100 | ||

Max tablet diameter (mm) | 25 | 16 | 13 |

Max length of non-round tablet (mm) | 25 | 19 | 16 |

Max filling depth of 1st layer (mm) | 19 | 19 | 15 |

Max filling depth of 2nd layer (mm) | 6(8) | 6(8) | 6(8) |

Max tablet thickness(mm) | 12 | 12 | 12 |

Middle die height(mm) | 23.8 | 22.22 | 22.22 |

Weight(Kg) | 4200 | ||

Machine size(mm) | 1180X1180X2035 | ||

Controlling cabinet size(mm) | 704X400X1100 | ||

Main features of the intelligent rotary pill press machine are as below:

1.Interchangeable turret, Convenient for machine cleaning and changing over, which improves the production efficiency very much;

2.Vertical powder feeding and large diameter hopper of the Calcium Tablet Press can handle powder of bad fluidity, suitable for pressing non-granulated powder;

3.Full servo control for press rollers position and dosing adjustment. High precision;

4.Pressure of all the 3 rollers can be displayed on the touch screen;

5.No hand wheel design. All operation can be finished on the touch screen;

6. This full automatic high speed pill tablet press machine is equipped with electronic records and signatures, which meets the FDA.

7. Germany branded pressure sensors under the roller can monitor the pressure and the filling quantity real time, which help operator to control the tablet weight very accurately.

This Calcium Tablet Press machine is very suitable for pharmaceutical tablet pressing factories who do the mass prodution of medicine tablets.

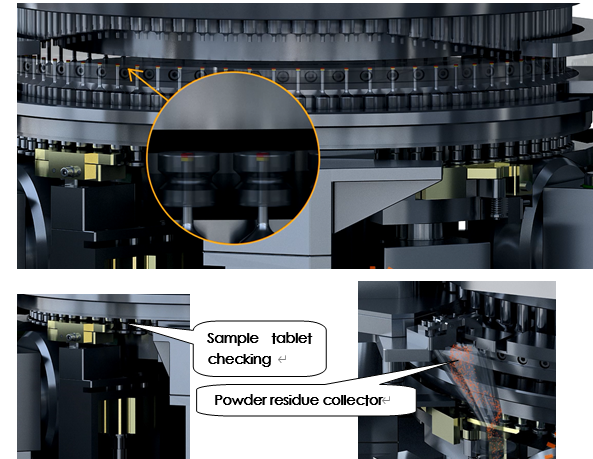

Three groups of pressure rollers press the every tablet three times

Double layer function is optional on this high-speed pill pressing machine

If extra set of material feeding device is added onto this full automatic pill making machine, double-layers of tablets can be pressed. The 1st roller presses the first layer, and the 2nd & 3rd rollers press the 2nd layer and complete the formation of the tablets.

Two sets of servo motors control the material filling at very high precision, material filling accuracy: 0.01mm. Three sets of rollers are also controlled by servo motors, adjusting accuracy is 0.1KN; This why the two layers tablet pressing machine has very high accuracy and very high level of automation.

The Lubrication system of this high speed tablet press is full automatic.

The automatic oil lubrication function is realized by setting the lubrication time; The lubrication system will give warning when the lubrication oil is in lack it will stop working automatically when the lubrication pressure is abnormal.

Centralized automatic control mode is adopted in the grease lubrication system of this milk tablet press machine. Thin oil lubrication system and centralized grease controlling lubrication system both adopts USA branded device;

The residue powder collection device on this mint candy making machine is made of aluminum alloy and have a 5-layer structure inside which can be disassembled and cleaned easily. it can absorb the residue powder on the rotating pale very effectively and keep the chamber of the high speed intelligent tablet press very clean.

Five layers Residue powder collection device

Punching head protection

The punch pressure of this automatic tablet press machine will be monitored during the pre-pressure stage, and turret will stop rating immediately if the pressure is beyond max limit before the punch goes into the main-pressure stage, which prevent the punches from damage(any other pneumatic or hydraulic protection system on other high speed rotary pill press machines can be activated only after the punches goes into the main pressure stage, which means the first 1 or 2 punches are already damaged when the protection system works)

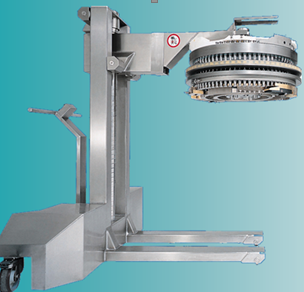

Removable rotating turret

The rotation turret of this high production capacity rotary tablet press can be moved out as the picture, and users don’t need to make any change to the machine when they exchange different types of tooling (D/B/BB)