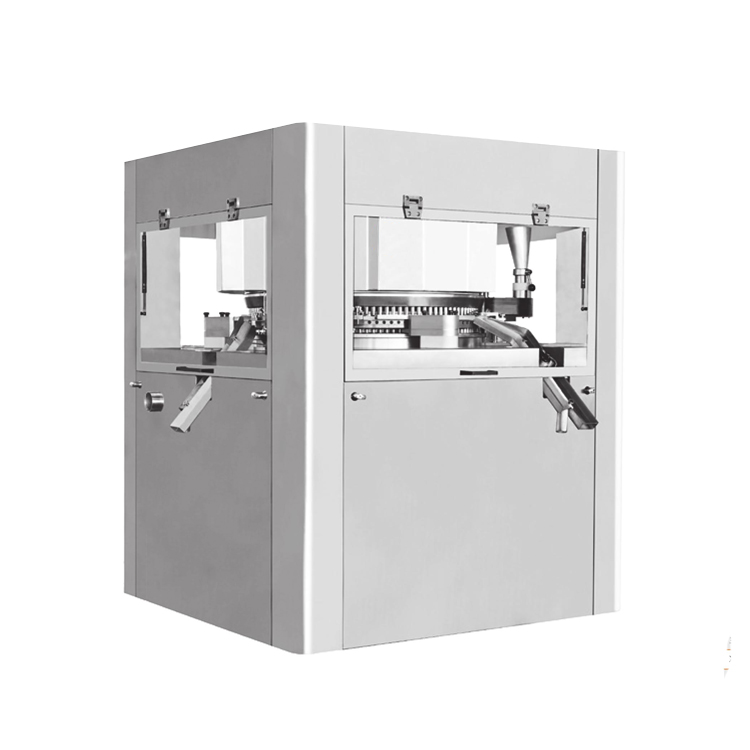

High Speed Rotary Tablet Press Machine

- TP

- China

- 30 workding days

- 40~80 sets/month

Common features of this rotary tablet press :

This high speed tablet press has PLC control with automatic protective function; Touch screen operation, operation menu is very brief and easy for understanding;

force feeding system of the automatic rotary tabelet press machine has good applicability to powder; Automatic lubrication system can reduce the noise and abrasion of the automatic rotary tablet press machine very effectively, and prolong the life time of the tablet press punches and dies.

Auto adjusting of the powder filling quantity; the pressure of every punch of the high speed tablet press can be monitored and displayed on the touch screen; Defective rejection system can be rejected automatically from the high speed pill press machine.

High speed rotary tablet press machine GZPK370

pressure system of this high speed tablet press:

There are Pre-pressure and main pressure on this automatic rotary tablet press machine, compact design and five-pole construction of this full automatic pharmaceutical pill press mahcine is to ensure no deforming upon heavy load pressure and steady performance, increasing tablet weight control accuracy and tablet hardness control.

Force feeding system of this high speed pill press machine:High precision, easy removable force feeder of this high speed pill press mahcine is with two agitators for improving granule fluidity to ensure precision feeding, which make the full automatic pharmaceutical pill press machine perfom more effectively and accurately.

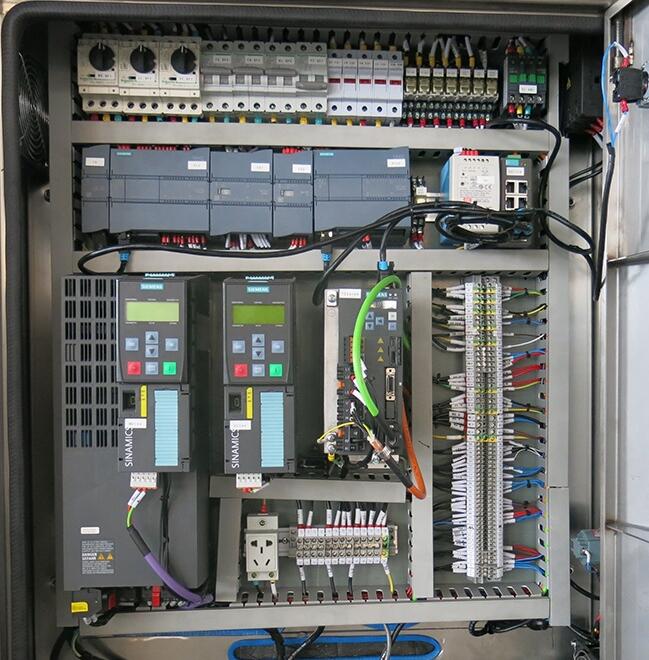

Reliable Electric System of this full automatic pharmaceutical pill press machine:

Advanced and reliable electrical components are applied on this rotary tablet pres, and spare parts from world leading suppliers to ensure the program control and interlock protection of this high speed tablet press. The famouse brand of electric parts help to make the high speed tablet press work more accurately.

Intermittent rated tiny flow auto pressure lubrication system of this high speed tablet press has high precision central lubrication pump and distributing value to ensure full lubrication of the punches and tracks on this automatic rotary tablet press machine, as well as to avoid lubrication contamination. And the lubrication system of this high speed tablet press helps to enlong the rotary tablet press machine's working life.

Touch screen is applied on this full automatic pharmaceutical pill press machine;

The touch screen of this automatic high speed tablet press is very convinient and customers can operate the automatic rotary tablet press machine very easily by touching the touch screen.

Main Technical Data of this automatic pill press machine

Product No. | GZPK370-26i | GZPK370-32i | GZPK370-40i |

Quantity of Punch & Die (set) | 26 | 32 | 40 |

Tooling Type | D | B | BB |

Main pressure (kn) | 100 | 100 | 100 |

Pre-Pressure (kn) | 16 | 16 | 16 |

Max. Dia. of Tablet (mm) | 25 | 16 | 13 |

Max. Thickness of Tablet (mm) | 1~8mm | 1~8mm | 1~8mm |

Max. Depth of Filling (mm) | 20 | 20 | 20 |

Middle Die Diameter (mm) | 38.1 | 30.16 | 24 |

Punch diameter (mm) | 25.35 | 19 | 19 |

Turret Rotation Speed (r/min) | 13-110 | 13-110 | 13-110 |

Production Capacity (pcs/h) | 20000~171600 | 25000~211200 | 31000-264000 |

Tablet outlet | 1 | 1 | 1 |

Voltage (v/hz) | 380/50 | 380/50 | 380/50 |

Motor Power (kw) | 7.5KW | 7.5KW | 7.5KW |

Outside Size (mm) | 820×1100×1750 | 820×1100×1750 | 820×1100×1750 |

Weight (kg) | 1600 | 1600 | 1600 |

Above production capacity of the high speed pill press machine is available when the tablet size is small and material has good flowability and formulation. Actual production speed of this high speed pill press machine is different if the material and sizes of tablets are different.

The punches and dies for the automatic rotary tablet press can be customized according to customer's requirement.