Automatic Blister Packing Machine

- TP

- Shanghai,China

- 20-25 days

- 30 units per month

1. The latest domestic high-power transmission mechanism is adopted on this automatic blister packing machine , and the main transmission shaft is driven by the chain to eliminate the errors and noise of other gear transmissions.

2. The electrical appliance on this small blister packing machine adopts the imported control system, which can be configured according to customer requirements, lack of materials missing and missing devices and missing particles detection and removal device.

3. The whole manual blister packing machine adopts segmented combination: PVC forming, feeding, heat sealing is one segment, and tropical aluminum cold forming, heat sealing, and punching are divided into one segment for split packaging.

4. Using photoelectric control system, PVC, PTP, rigid aluminum packaging automatic feeding, waste edge automatic punching device to ensure the long-distance multi-station synchronization stability.

5, This liquid capsule blister packing machine can be equipped with additional photoelectric detection and correction device, imported stepper motor traction, graphic and text printing and packaging, optimize packaging grade.

6. This semi-auto blister packing machine is suitable for: blister-sealed packaging of capsules, plain tablets, sugar-coated tablets, gel pills, injections, special shapes, etc.

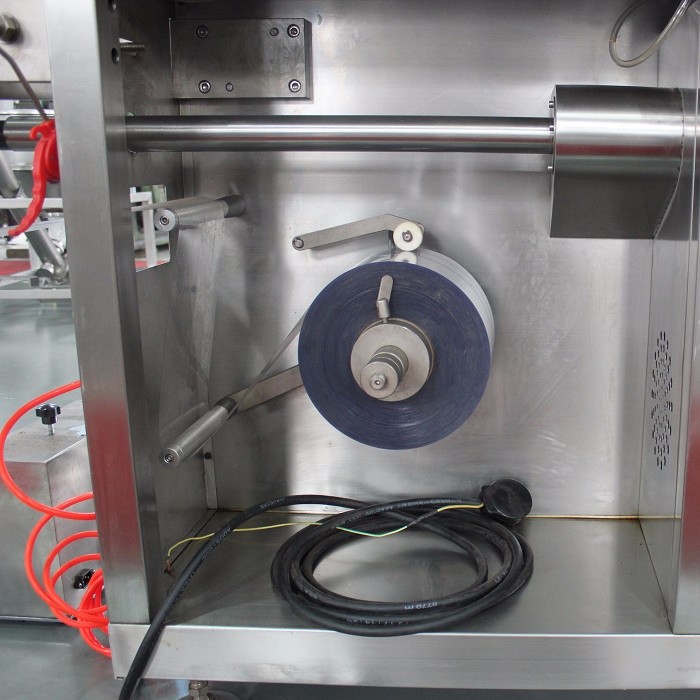

DPP multifunction automatic blister packing machine is an new product developed by our company, collecting the advantage of aluminum/plastic packing machines at home and abroad, and the important parts are adopted on this liquid capsule blister packing machine. This Semi-auto blister packing machine is suitable for packing tablets, sugar-coated tablets, capsules as well as small food, hardware and electronic components. This manual blister packing machine combines ten functions to a whole such as web cutting, aluminum/plastic feeding, blister forming, filling, aluminum foil printing, aluminum/plastic heat-sealing, batch number printing, cross-hatching creasing, sheet cutting, counting etc. It’s unnecessary to be operated by manual during production, the packed products have fine sealing, safe and hygienic. The performance and price of this small blister packing machine is better than the similar products abroad.

This automatic blister packing machine was checked and approved by scientific and technological achievements evaluation of Shanghai, listed as one of the key national new products and national improvement and GMP carried out in China. Many of these small blister packing machines have been sold to the pharmaceutical factories, big and medium-sized hospitals throughout the nation, and exported to India, Pakistan, Malaysia, Burundi, Hongkong and Taiwan etc, and well appreciated by customers.

2.Main performance & Feature

(1)This Semi-auto blister packing machine has frequency stepless speed regulating, the punching frequency reaches 6-35times per minute.

(2) The stroke can be adjusted within 40-110mm, which is easy to adjust with correct synchronization.

(3) Adopts plate-type mould, positive-pressure forming, featured by batch number printing, creasing and cutting, aluminum-foil/plastics automatic feeding, automatic alarm for broken-piece and finished-piece and automatic stop etc.

(4) This Semi-auto blister packing machine is quipped with one set general feeder, which filling percentage reaches 99.5 and above. The feeder is fitted with dust exhaust joint so can overcome the dust problem during feeding.

(5) This small blister packing machine adopts registering matching heating so as to reduce the heat energy loss of heater to the least, and the required temperature will be greatly reduced.

(6) This automatic blister packing machine has small volume, light weight, cramped structure, easy operation and maintenance.

3. Min Technical Parameters for DPP150 model of blister packing machine

Description | Unit | Specifications |

Punch Speed | Times/min | 15-35 |

Adjustable stroke | mm | 55-120(freely adjusted) |

Max. Forming Area | mm×mm | 120×110 |

Max. Forming Depth | mm | 14 |

Main Motor Power | Kw | 1.5 |

Upper Heating power | Kw | 0.8 |

Lower Heating Power | Kw | 0.8 |

Heating Power for Heat Sealing | Kw | 1 |

Air Pump Volume Flow | m3/min | ≤0.15 |

Air Pressure | Mpa | 0.1-06 |

PVC for Medicine | mm×mm | 0.25×130 |

Aluminum foil | mm×mm | 0.02×130 |

Overall Dimensions (L×W×H) | mm×mm | 2300×560×1410 |

Machine Weight | kg | 600 |

Above technical data is for reference only, actual technique data is confirmed according to customer's detailed products and requirement.

How to operate this automatic blister packing machine:

1. The green indicator light on this Semi-auto blister packing machine is on when the power is turned on, and the two heating switches for forming up and down and heat sealing are turned on respectively. The temperature controller controls the forming temperature, which is generally preset at 100oC. The second temperature controller controls the heat seal, and the temperature is preset at 130oC ~ 140oC. Pre-set temperature for upper and lower molding and heat-sealing temperature controller;

2. Lower the pressure block on the lifting roller, the temperature of the forming heating plate is in place, and then turn on the main machine. The plastic PVC is formed first. The aluminum foil will drive to the interception.

Observe whether the plastic (referring to the new PVC surface of the board) is shifted left and right. If there is a deviation, adjust the lead roller base to move the lead direction.

3. If the aluminum foil is deflected from side to side, the adjustable joint roller seat handwheel can be adjusted. If the front-back deviation is adjustable, the cabinet moves.

4. After the heat-sealing and loading are normal, open the feeder switch and the shutter appropriately, so that the medicines (tablets, capsules, and clothing) can enter the feeding chamber in an appropriate amount. If there is a small amount of cylinder material, it can be filled manually. If the medicine is brought into the heat, When sealing the mold, it will seriously affect the synchronization. Therefore, when the aluminum foil is sealed, the mold must be stopped and processed.

5. Due to the increase of the weight of the medicine, the aluminum foil pulling force and the temperature of the machine change gradually, which may cause the molding and heat sealing to be out of sync. If it is advanced or lagging, first check whether the plastic PVC and aluminum foil are shaded, and then use the fine adjustment mechanism on the machine to adjust. The fine-tuning mechanism is adjusted backwards or backwards due to the adjustment distance of the mold. Therefore, it should be placed in the neutral position before starting. It can be moved forward and backward. It can also be adjusted by the movement of the front box. After the correct movement, the plate must wait for more than a dozen plates to be correct. Tune up and down.

6. The heat sealing quality of plastic and aluminum foil (even, firm and flat bonding) is evidenced by the temperature or pressure and the flatness of the textured plate. If there is a poor heat seal, the temperature should be generally lower, the pressure should be slightly lower, and the regulator positive temperature. Adjust screw pressure.

7, punching deviation, cutting off with a layout offset. Stop the machine to move the manual adjustment box, and the mold can be shifted.

8. In daily operation knowledge, you must understand the structure principle of the machine for the operation. The cam drives the roller of the jack seat, the upper and lower strokes, the position of the upper cover template is fixed, and the blister is in a bad state. Pay attention to the lower forming mold or heat seal. At the top dead center, fix the column nut tightly. If you don't pay attention, it will be prone to failure, and the roller pin needle pressed by the ejector pin will die.

Automatic blister packaging machine Note:

1. Please read this manualfor this automatic blister packing machine carefully before operating and using. In case of incorrect operation and damage to the machine.

2. Check whether the ground levelness is balanced before installation.

3. Connect the ground wire at the location specified by the grounding label.

4. Full-time personnel training operation and maintenance.

5. The machine should be kept tidy.

6.All parts must be refueled before the machine is produced.

7. When the machine leaves the factory, the transmission case strap must be lubricated. It must be refueled before production.

8. It is suggested that this machine should be an oil-free air compressor.

9. The pressure in the forming, heat sealing, indentation and other parts should not be too large, otherwise it will affect the service life. There should be about one millimeter of floating space for forming and indenting the cushion.

10. When the machine is in operation, it is strictly forbidden to touch the running parts (especially the longitudinal and horizontal seal heating parts) by hand to ensure the safety of people and the machine.