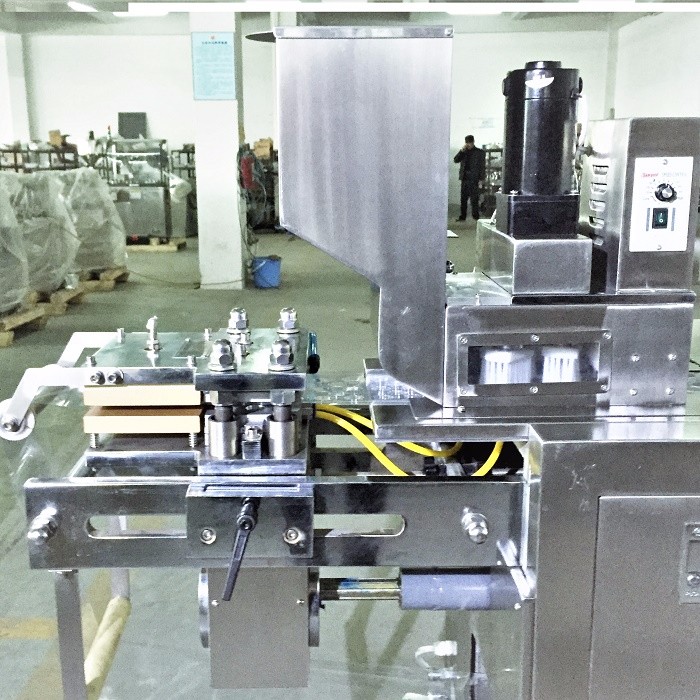

ALU ALU Blister Packing Machine

- TP

- Shanghai,China

- 20-25 days

- 30 units per month

1. Alu alu blister packing machine adopts plunger type metering pump for filling,it is high in precision, the structure of the pump is easy to install and uninstall, and convenient for cleaning and sterilizing.

2. PLC control system, colorful touch screen are used on this pills blister packing machine;.

3.The filling head of this alu alu blister packing machine has the anti- dropping device;

4. The filling precision is ±05%, the filling volume is 5-25ml( can be customized)

5. The frame of the alu/pvc blister packing machine and contact parts with material are bothmade from stainless ste

6.ALU/PVC blister packing machine meets with the GMP COMPLETELY.

Product scope and features of this ALU ALU blister packing machine:

1. The latest domestic high-power transmission mechanism is adopted on this pill blister packing machine, and the transmission shaft is driven by the chain to avoid the errors of other gear transmissions.

2.Electrical appliances adopt imported control system, which can be configured according to customer's requirements for lack of materials, missing supply and missing particles detection and removal device. Adopt imported frequency converter.

3. The whole ALU/PVC blister packing machine adopts segmented combination: PVC forming, feeding, and heat sealing are one section, and tropical aluminum cold forming, heat sealing, and punching are one section can be split packaging.

4. photoelectric control system is used on this tablet blister packing machine, PVC, PTP, tropical aluminum packaging automatic feeding, waste edge automatic receiving device to ensure Multi-station long-distance synchronization stability.

5, This tablet blister packing machine can be equipped with additional photoelectric detection and correction device, with imported stepper motor traction, graphic printing and packaging, optimize packaging Grade.

6. This tablet blister packing machine is suitable for: capsules, plain tablets, sugar-coated, plastic pills, injections, special shapes, etc. as well as medical devices, light food, electronics

Component blister sealed package.

Automatic blister packaging machine workflow is as below:

1. Forming (up and down heating)

2. Heat sealing (upper heating)

3.Code

4. Indentation (can be trace heated)

5.Cutter

6, molding output finished product

Operation rules of pills blister packing machine

1. Purpose: To ensure that the operation of the flat-type blister packaging machine is standardized and standardized, to ensure the quality of the packaging, and to extend the service life of the machine.

2. Scope: suitable for the operation of the flat-type blister packaging machine.

3. Responsibility: The operator of the flat-type blister packaging machine is responsible for the implementation of this standard, and the equipment technician is responsible for supervision.

Item | Name | Spec/model | Brand | Qty |

1 | Traction Cylinder | SSA φ32×15 | Kaogeer | 2 |

2 | Main Motor | CH32 ZHP1500W | ZhejiangTaibang | 1 |

3 | Forming heating plate | 170×130×20 | Zhejiang hongxing | 2 |

4 | Heating sealing plate | 158×110×20 | Zhejiang hongxing | 1 |

5 | Frequency inverter | DVA-3S0015G | Delaire | 1 |

6 | Feeding motor | 802YT52 J15 | Ryan Maili | 1 |

7 | Waste material collection motor | 4GN-15-K | Ryan Maili | 2 |

8 | Thermocouple | WRKT-01 | Tes Taiwan | 2 |

9 | Air circuit breaker | C65N-20A/3P | Schneider | 1 |

10 | Air circuit breaker | C65N-10A/1P | Schneider | 2 |

11 | Air circuit breaker | C65N-6A/1P | Schneider | 1 |

12 | PC controlling panel | / | Wenzhou Tuanjie | 1 |

13 | Solid relay | SSR-40DA | Fotek Taiwan | 2 |

14 | Controlling Transformer | JBK3-63 | Zhejiang Chint | 1 |

15 | Electromagnetic valve | SG4V210-08 | AirTA | 3 |

16 | Emergency button | XB2-BS542 | Schneider | 1 |

17 | Photoelectrical sensor | J12-A4JK | BDL | 3 |

18 | Touch screen | ST700 | Siemens | |

19 | PLC | CPU224CN | Siemens | |

20 | Temperature module | EM231CN | Siemens | |

21 | Speed control module | EM232CN | Siemens | |

22 | The encode | E6B2-CWZ6C | Omron |

Above data is for reference only, final actual data and device brands depends on the agreement between the buyer and us.