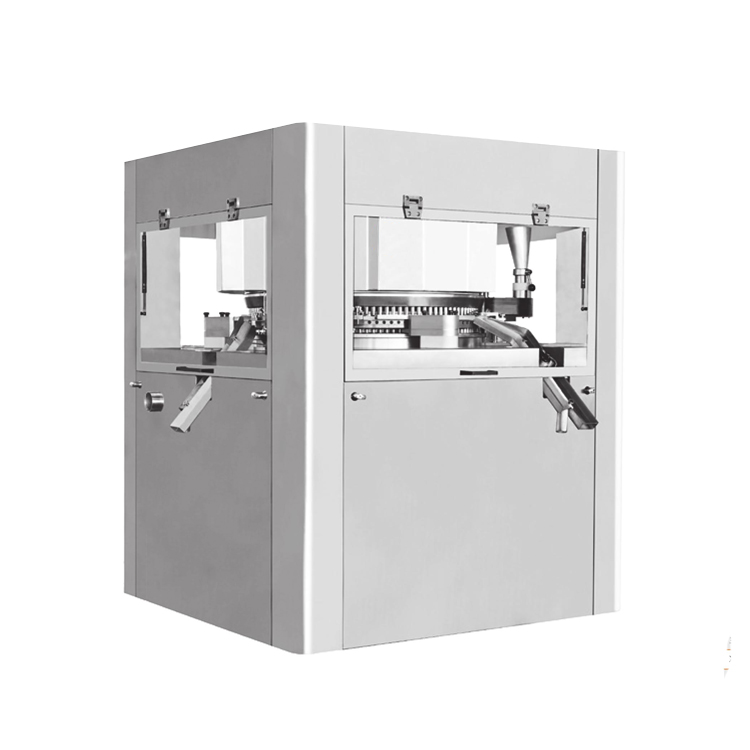

high speed automatic tablet press

This high speed rotary tablet press machine has two sets of pressing units, pre-pressue:100KN and main-pressure : 100KN, which make this high capacity tablet press machine have the excellent performance in the mass production of medicine tablets.

Sevo motors are dopted on this full automatic rotary tablet press, and Variable Frequency Speed Regulating make the operation of the machine very easy.

Thickness of the tablet, fill depth and pressure data can be displayed on the touch screen of this high capacity tablet press.

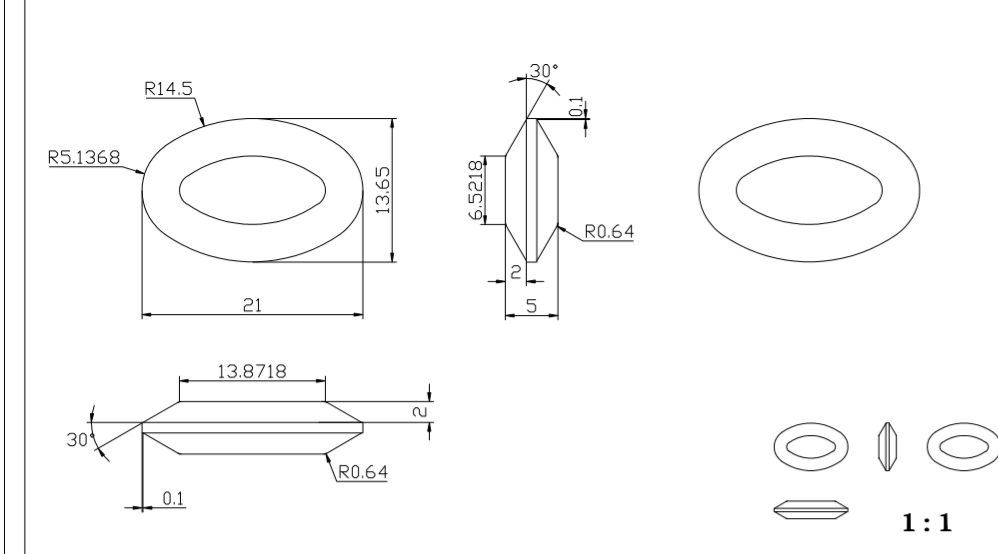

GZPK720 high-speed automatic rotary tablet press machine has advantages of high accuracy, high speed and high performance. The advanced and reasonable design is the foundation of extraordinary quality to meet GMP standard, this automatic rotary pill press machine can press two layers, annular, round, engraved and irregular tablets in pharmaceutical, food, and chemical industries.

Machine Photo of this high speed automatic tablet press

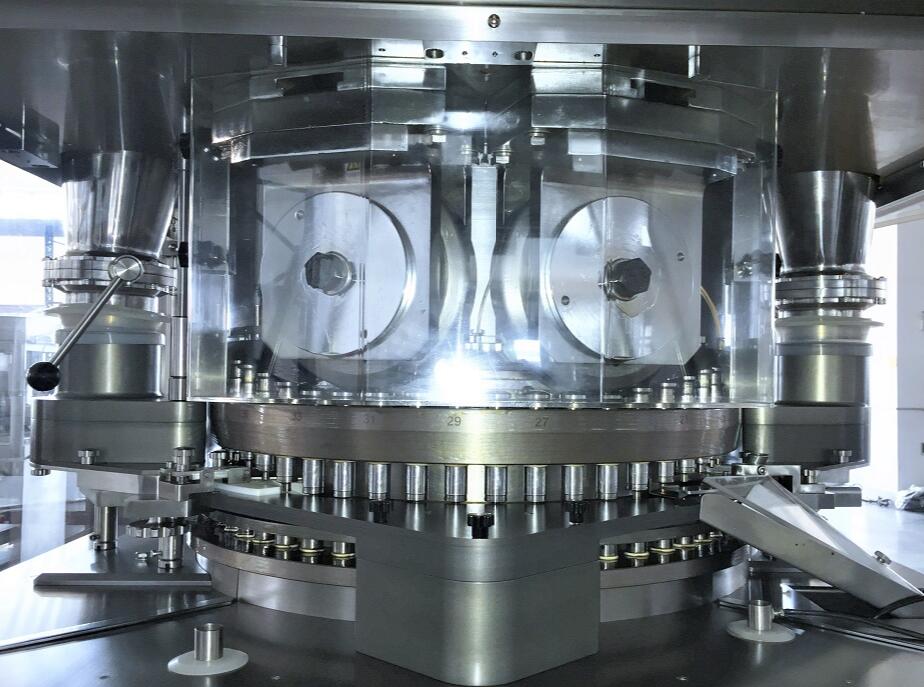

1. Double-sided discharge chutes, high productivity. No handwheel with machine, automatic drive by synchronous motor, this full automatic high speed rotary tablet press can completely realize automatic production. The control cabinet of this high production capacity rotary tablet press is independantly installed, and separated production area from operation area to ensure the safety for operator and sanitation for production.

Vacuum collector nozle keeps the die table clean effectively.

2. Main pressure system, pre-pressure system, filling system, feeding system on this high speed intelligent tablet press adopt modular design. Simple structure. These modular parts can be freely adjusted or removed. Non-interference between maintenance are easy. The main pressure and pre-pressure are the same structure which can be interchanged with each other. Both main pressure and pre-pressure are all 100kn which make this high technoloy tablet press form tablets very easily.

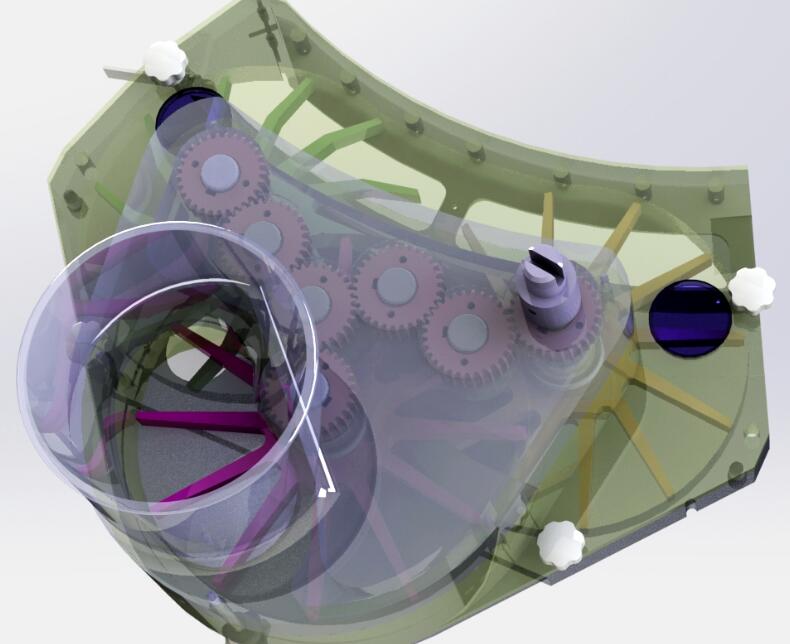

3. Tri-wheeled double layer feeding system is adopted on this full automatic rotary tablet press machine.

The upper impeller can increase powder flowablity.

The lower impellers are used for feeding and dosing to ensure the uniformity of feeding.

Use servo motor to adjust dosing cam track which can control filling depth to ensure accurate dosage.

4. Force-feeding device of this full automatic rotary pill press machine controls the flow of powder and ensures the accuracy of feeding. The force feeders of this pharmaceutical tablet press machine can be easily removed or installed. No dead area in press chamber and easy to be observed and cleaned.

Main Technical Data of this

full automatic rotary tablet press

Model No. | GZPK720-51 | GZPK720-65 | GZPK720-73 |

Quantity of Punch & Die (set) | 51 | 65 | 73 |

Tooling Type | D | b | bb |

Max. Pre-pressure (kn) | 100 | 100 | 100 |

Max. Pressure (kn) | 100 | 100 | 100 |

Max. Dia. of Tablet (mm) | 25 | 16 | 13 |

Max. Length of Irregular Tablet (mm) | 25 | 19 | 16 |

Max. Depth of Filling (mm) | 20 | 18 | 18 |

Max. Thickness (mm) | 8 | 8 | 8 |

Dia. of Middle Die (mm) | 38.1 | 30.16 | 24 |

Punch Diameter (mm) | 25.35 | 19 | 16 |

Rotation Speed (r/min) | 8-80 | 8-80 | 8-80 |

Production Capacity (pcs/h) | 47000-470000 | 62400-624000 | 70000-700000 |

Motor Power (kw) | 11 | 11 | 11 |

Overall Size (mm) | 1300*1300*2000 | 1300*1300*2000 | 1300*1300*2000 |

Weight (kg) | 5500 | 5500 | 5500 |

The above production capacity of the high-speed medicine pill making machine is for reference only, and actual tablet pressing speed depends on the characteristics of the raw powder material and the tablet sizes and shapes.