High Speed Tablet Press Machine GZPK720

- TP

- CN

- 40 working day

- 10sets per month

This high speed tablet press machine is widely used in pharmaceutical care industry,and get very positive feedback from the end-users. We can customize this high speed tablet press machine according to your detailed requirement.

We can produce 10 sets of this automatic tablet press machine every month, and we have installed this automatic tablet compress machine in many countries.

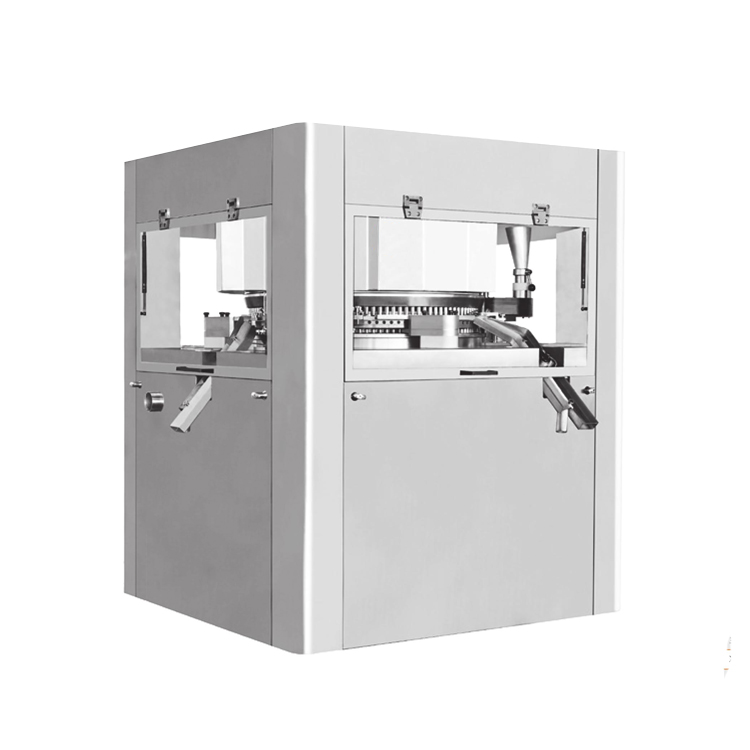

GZPK 720-99 High Speed Rotary Tablet Press Machine with full automatic function

GZPS-720 Full-automatic Double Side High-speed Tablet Press Machine

Technical Data for this automatic tablet compressmachine:

Working Environment for this high speed tablet making machine:

The working environment conforms to relevant requirements of GMP specification.

Material Pressing Requirement

Granule Requirement

· Granule size scope for this high speed tablet press machine: 14-60 meshes, good compressibility and mobility;

· Synthetic medicine starch tablet: the granules should be uniform and moisture should be less than 3%;

· the proportion of fine powder (above 60 meshes) in the granules should not exceed one third;

· Traditional Chinese medicine granules: pure extract, semi-extract and raw powder granules should not be moist and should have certain mobility.

Dry Powder is applicable on this GZPK720 series automatic high speed tablet compress machine

· This high speed tablet press machine is suitable for pressing the powder directly. The pressed powder should have certain compressibility and fluidity.

Tablet Form Requirement

Can compress the ordinary round tablet, large tablet, special-shaped tablet, single-double-sided lettering tablets.

Power supply Requirement

380V, 50Hz, three-phase five-wire system, no mutual interference between N line and PE line.

Technical Parameters of GZPK Dual-discharge High-speed Tablet Press (GZPK-51/65/83)

| The number type | GZPK720-99 |

| The punch number83 | 99 |

| Plate speed /R.P.M | 8-80 |

| Maximum output (10k/h) | 95000-950000 |

| Main motor power (KW) | 11 |

| Maximum pressure KN (10KN= 0.98t) | 100 |

| Maximum tablet diameter( mm) | 10 |

| Maximum tablet thickness(mm) | 8 |

| Pitch diameter(mm) | 720 |

| Push rod diameter(mm) | 16 |

| In the mold diameter(mm) | 24 |

| Maximum prepressure (KN) | 100 |

| Rotating speed of punch disk / R.P.M | 8-80 |

| Weight (Kg) | 5500 |

Cope of Application:

This New type high speed automatic rotary tablet press will help you to increase your production capacity effecetively and upgrade your product quality standard efficiently.

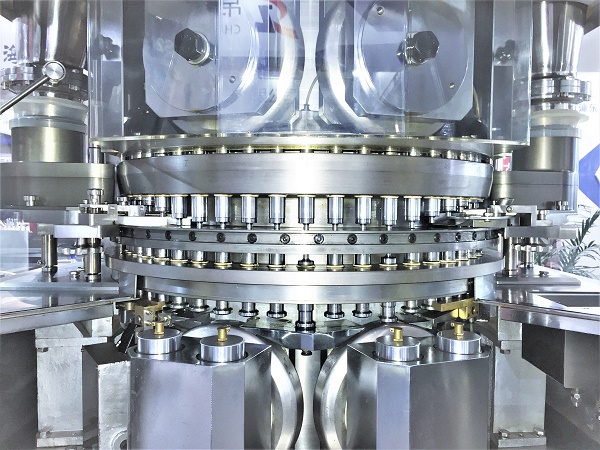

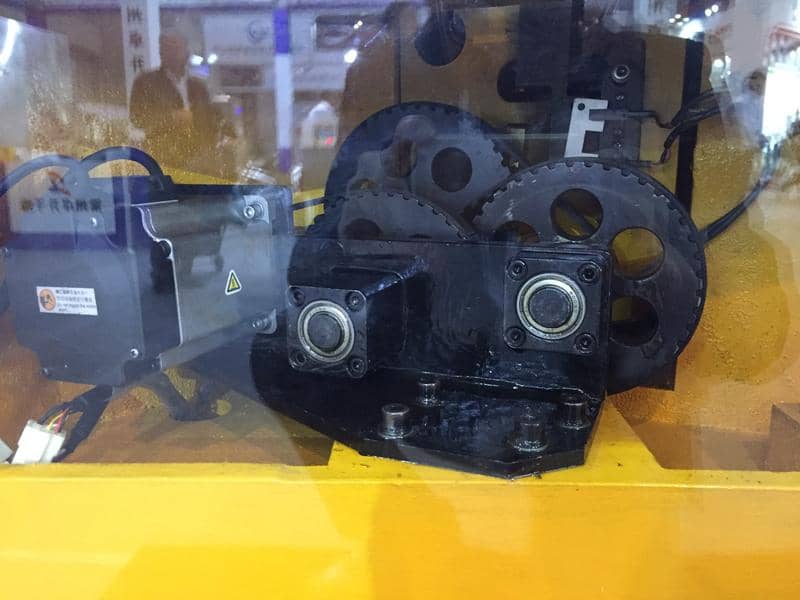

This high speed rotary tablet press machine has two groups of pressing rollers and each group is composed of main pressure and pre-pressure rollers. Each team of pressing rollers provide maximum pressure of 150KN.

Full Features of this high speed tablet press machine:

1. This high speed rotary tabletting machine is fully-enclosed with stainless steel covers, which is in accordance with the GMP requirement.

2. This high speed tabletting machine's pressing chamber is sealed with four transparent windows,so the powder can be contained inside the pressing chamber of the automatic tablet press machine and the operator can observe the pressing work easily.

3. The automatic rotary tablet press machine can be loaded with EU D tooling, EU B tooling, EU BB tooling and EU BBS tooling, and different shapes of tablet molds can be customized according to demand.

4. Emergency controllers are placed on a hand hold controlling pannel, which can be held by hand easily and move around the machine if necessary, which make it very convinient for the operators to operate the automatic tablet press machine.

5. Over tight protection devices are adopted on both the upper and lower punches

If the upper or lower punches get too tight during the moving, the machine will stop immediately to prevent the punch rods colliding onto the track.

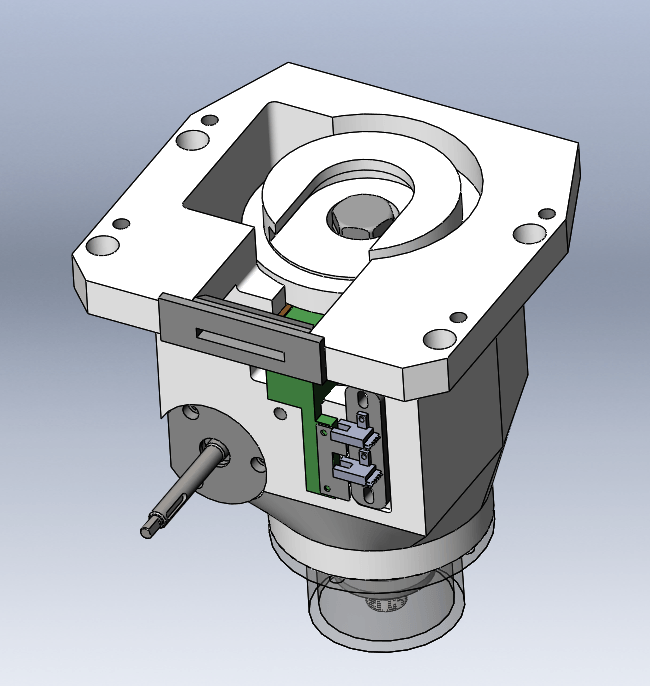

6. Automatic tablet weight controlling system is applied on this high speed tablet press machine.

Once the tablet weight becomes little less or more, the automatic tablet weight controoling system will be activated immeditately and the filling depth will be adjusted slightly and exactly until the tablet weight goes back to standard limit.

7. Defective tablet rejection system is adopted on this automatic tablet press machine;

Once the tablet weight controlling system can not correct the tablet weight, the defective tablet rejection system on this high speed tablet press machine will start working as soon as the tablet weight goes beyond the maximum or mimium limit to the tablet weight.

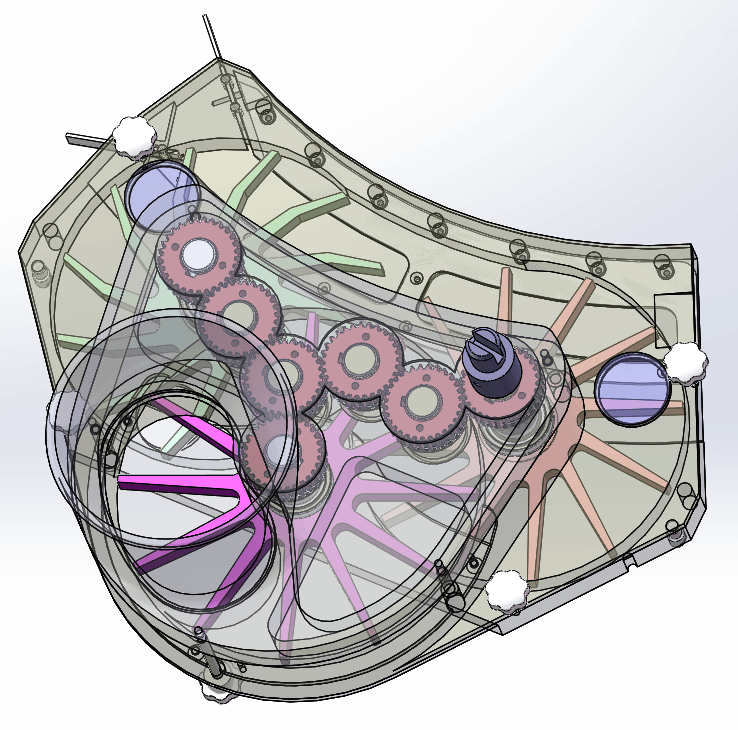

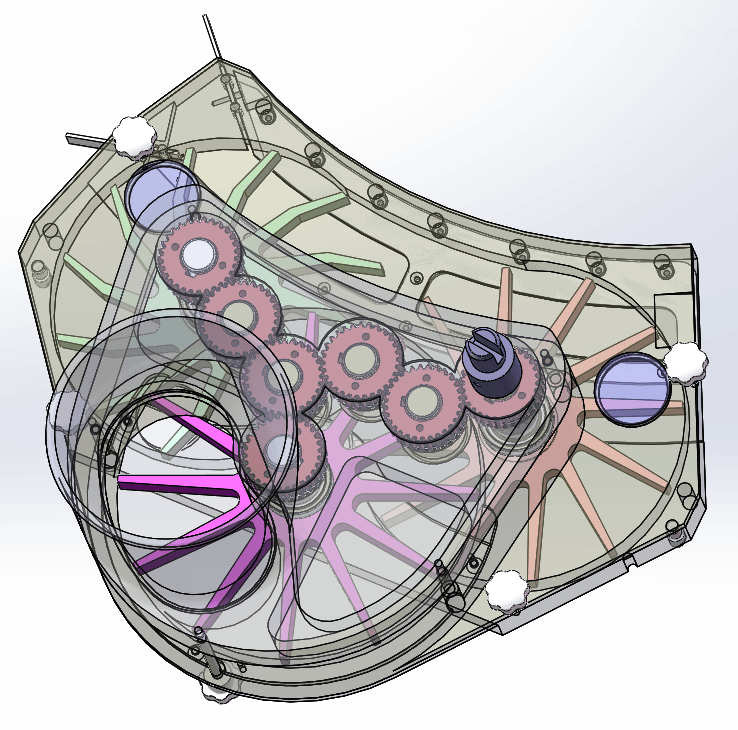

Lower Pressing Wheel Mechanism

Punch Disk Structure

· Middle die plate on this GZPK720 high speed tablet machine is made of 2Cr13 stainless steel and is processed by laser quenching to make the surface hardness above HRC55, thus having good hardness, wearing and corrosion resistance.

· Upper and lower punch holder turret are made of QT600 and the surfaces thereof are coated with nickel-phosphorus for rust protection, so they have good wear resistance and lubrication.

· End face run-out of middle punch disk is less than or equal to 0.03mm.

· The permanent magnetic damper is adopted as the lower punch damper, and the lower punch pin is not contacted withg the damper pin to prolong the service life of the punch pin, and ensure the damping consistence of the lower punch pin, and avoid bounce and free drop of the plunger under high-speed rotation, and reduce rotation noise.

· The upper punch disk is surrounded by a shield, and the air inlet fan is installed at the middle of the roof to keep positive pressure for the upper punch disk and ensure difficult dust entry and convenient cleanin.

Other Features

Other Features

Tablet weight precision of this high speed tablet press machine is within 3% (the tablet weight precision of the tablet press also depends on a variety of factors, material compressibility, tablet specifications and mold precision, etc.) The tablet weight can be controlled automatically according to the pre-set tolerance.

2. Thickness control accuracy 0.1mm(the thickness accuracy of the tablet press also depends on a variety of factors, the compressibility of materials, the composition of the tablet, the precision of the mold and the quality of the supporting conditions of the machine, etc.)

3, This high-speed tablet press machine's pressing chamber should be closed, no pollution, easy to disassemble, easy to clean, and with dust absorption, self-locking door function. The working surface of the high-speed tablet press is smooth and clean outside, without scratches or rust. The coating color and luster is consistent, does not bubble, does not fall off. The overall use of oil drawing board, smooth, smooth surface; All non - stainless steel parts are polished and electroplated with part Numbers engraved on the surface. External appearance of a piece of refinement.

4. This automatic high speed tablet making machine adopt symmetrical double-side feeding, double-side tablet pressing and double-side tablet design. Both the main pressure and the pre-pressure can reach 100KN, and both the main pressure and the pre-pressure can be detected. The main pressure wheel and the pre-pressure wheel are adjusted by synchronous motor, the adjustment speed is fast and the precision is high. Can reduce the amount of waste due to adjustment.

5. The device is equipped with material level sensor6. The equipment has online sampling function, which can adjust the sampling frequency and sampling amount.7, tick waste function, good film, waste film, sample classification export. Delay during startup or shutdown.