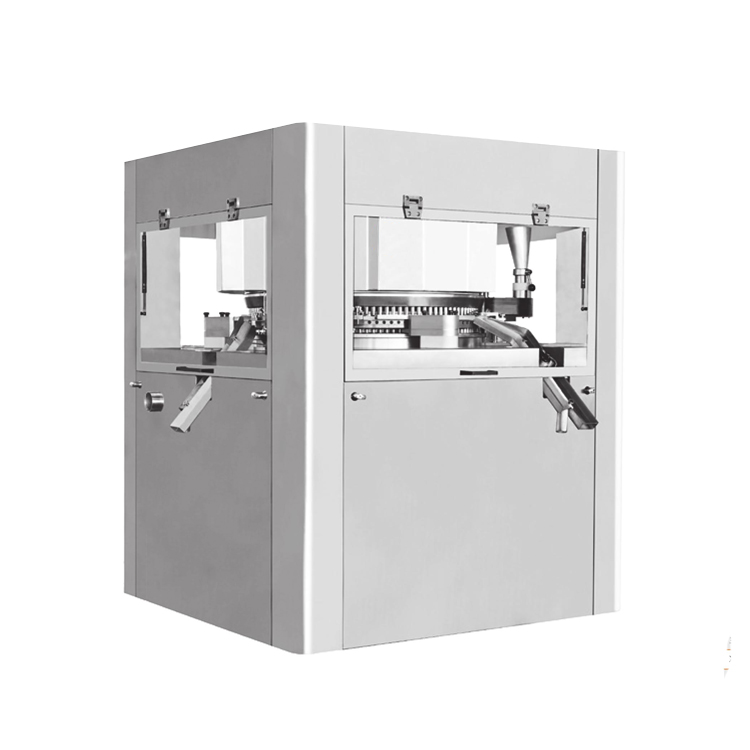

Full Automatic Rotary Pill Press Machine

- TP

- CHINA

- 35 days

- 60sets/month

This high capacity rotary tablet press machine has hand wheels, but the adjusting of the pressure, material filling depth, and the tablet thickness can be adjusted by both hand and touch screen. The punches pressure can be monitored and displayed on the healthcare tablet press machine's touch screen.

Our automatic high speed medicine pressing machine has the punches over tight protection system, force feeding device, over loading protection and erro warning. This fast speed rotary tablet making machine also has the automatic lubrication system.

Main machine technical data for Automatic Pharmaceutical Tablet Press Machine

Model No. | GZPK620-45 |

No. of Stations | 45 |

Tooling Type | D |

Production Capacity (pcs/h) | 432000 |

Rotation Speed (r/min) | 80 |

Main Pressure (kn) | 100 |

Pre-pressure (kn) | 16 |

Max. Tablet Dia. (mm) | Φ25 |

Max Length of Irregular Tablet (mm) | 25 |

Diameter of Die (mm) | Φ38.1 |

Max. Filling Depth (mm) | 20 |

Diameter of Punch (mm) | 25.35 |

Length of Punch (mm) | 133.6 |

Pitch Circle Diameter (mm) | 620 |

Motor Power (kw) | 11 |

Overall Size (mm) | 1510×1380×2000 |

Weight (kg) | 3800 |

B and BB punches and dies for rotary tablet press can be applied on the double discharge high-speed rotary tablet press on customers' requirement.

3. Main structure and functions for double sided tablet press machine

This equipment is double sided high speed rotary tablet press machine. It adopts double force feeding and double sided discharging system. 2 times powder filling, dosing, pre-pressing, main pressing and ejection, with the turret revolves one circle. Maximum output can reach to 432000 tablets/h. This high efficiency tablet press machine runs with reliable performance and low noise. It can press double layers tablet by changing a set of guide rails.

3.5 Feeding system

Tablet press machine adopts central feeding double impellers system, which in a period can help to keep tablet weight difference when there is no sufficient powder in hopper. Feeding system is driven by three phase asynchronous motor. Feeding motor is controlled by converter and keeps stable starting, overloading protection, accidental shutdown and speed adjusting, etc. It can effectively remit bad influence caused by powder fluidity and uniformity. Because of using enclosed forcing double impellers, requirement for granules is not strict. Also, it’s suitable for pressing dry powder directly, which can decrease or leave out granulation process.

Machine guide rail

Guide rails are like tracks for train. They are used for guide motion of upper and lower punches of the high-speed rotary tablet press. With limit of guide rails, tablet press punches move in set guide rails. Guide rails contains upper and lower guide rails. Upper guide rail is for guiding upper tablet press' punches motion and lower guide rail is for guiding lower punches motion.

All filling guide rails adopt cosine curve double side rail and lubricating points are increased, which guarantee life of guide rails and decrease punches abrasion and noise. There are 3 size feeding rails, which are used for pressing light, middle and thick tablets. The 3 size guide rails can be exchanged to meet different requirements.

Auto lubrication

Double lubrication systems are installed on this automatic high speed medicine pressing machine, one is grease lubrication, the other is oil lubrication. Grease is mainly for bearings and oil is mainly for parts like shafts.

Grease lubrication system of this automatic pill press machine is composed of semi-automatic manual injection pump and dill-down type distribution valve, which is easy for operator to accurately check the situation of oil path.

Amount of oil is controlled by electrical program. Volume of oil can be adjusted to avoid too much oil on upper press roller and lead to tablet contamination. A part of the cover plate of dust collection device is tightly covering on the middle plate. There are oil proofing rings on all punches to keep contamination from oil. Auto alarm for insufficient oil; no need human interference.