Automatic Pharmaceutical Tablet Press

- TP

- China

- 35 days

- 50 sets/month

Automatic Pharmaceutical Tablet Press model GZPK720i can press two layers of tablets with different colors, annular tablets and irregular tablets, suitablet for pharmaceutical factory, food and chemical industries. The tablets are pressed two times by main pressure and pre-pressing wheels.

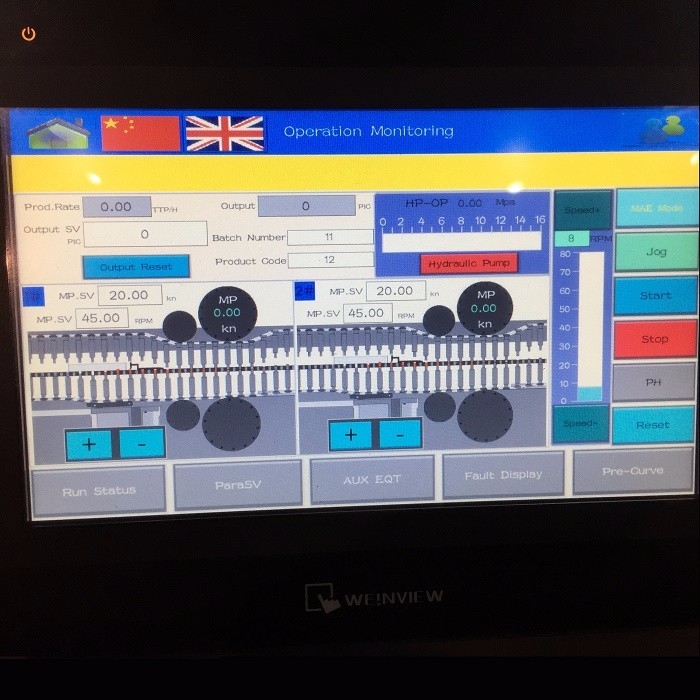

This GZPK720i automatic pill press machine has central auto lubrication system. Double-sided discharge. There is no hand-wheels, all the operation can be done on the touch screen. This automatic pill making machine adopts synchronous motor to realize the automatic production.

This automatic high-speed medecine pill making machine adopts encoder to coun the tablets. The automatic pill making machine aslo has the imported hydraulic pump to support the main presure and pre-pressure, and this high speed rotary tablet press machine is equiped with overloading protection system, and the machine will stop automatically when the pressure goes beyond the limit.

High Speed Rotary Tablet Press GZPK720I series

Performance

GZPK720i series Automatic Pharmaceutical Tablet Press Machine have advantages of high accuracy, speed and high-degree programmed combination of years of experiences on producing high-speed tablet press,These automatic high speed medicine pressing machines meet GMP standard, it can press two layers, annular, round, engraved and irregular tablets. And customized shapes are available.

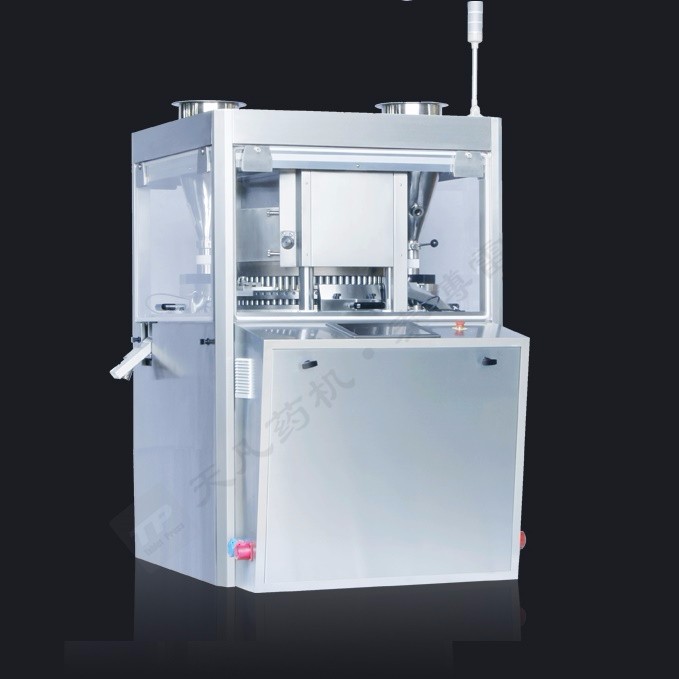

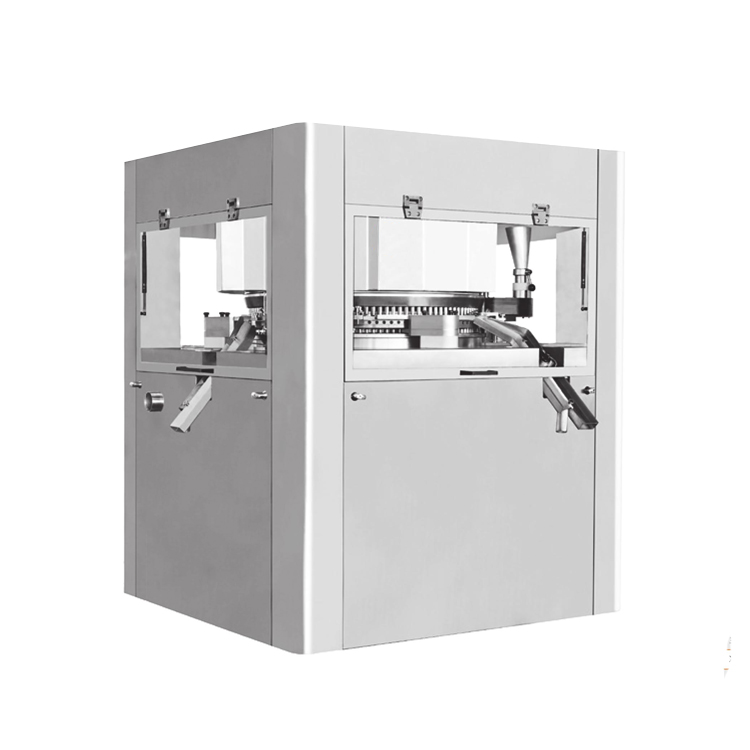

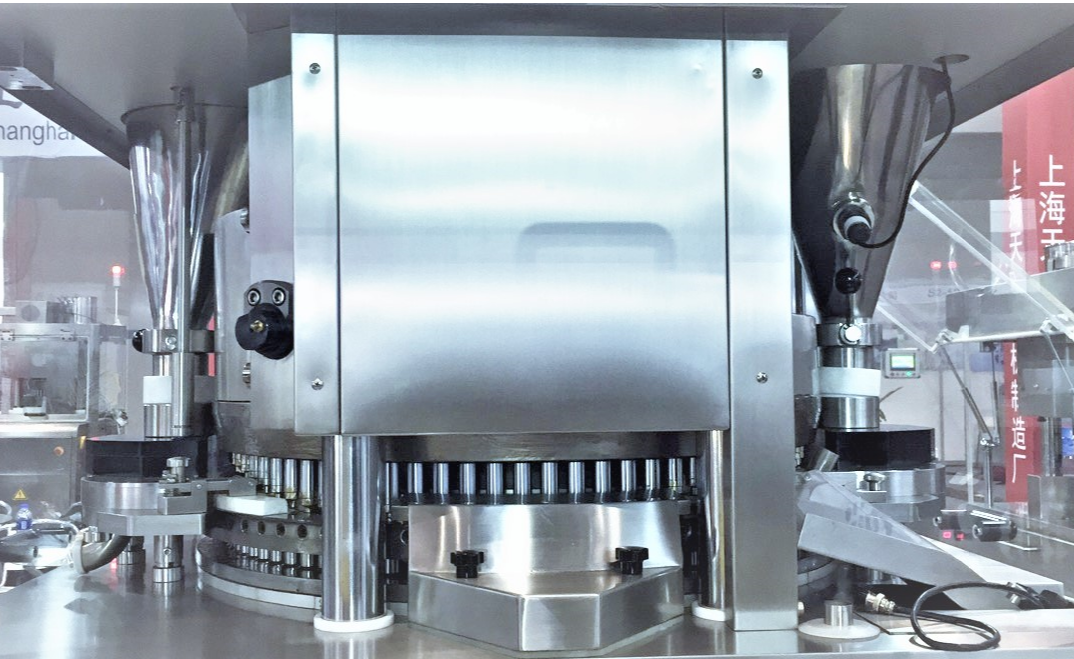

Machine Photo

1. This automatic pill making machine has two discharge chutes, high productivity. No handwheel with machine, automatic drive by synchronous motor, this high speed tablet machine can completely realize automatic production.

2. Main pressure system, pre-pressure system, automatic filling system, force feeding systems on this automatic pill press machine adopt modular designs, can be removed or added easily.

3. The full-sealed force feeder of the Automatic Pharmaceutical Tablet Press Machine can make sure the powder filling quanity is accurate, and the tablet weight is within the tolerance even when the powder flowability is not so good.The chamber is very easy to be cleaned.The material quanity inside the hopper can be monitored and the vacuum conveyor will be activated as soon as the material is below the limit.

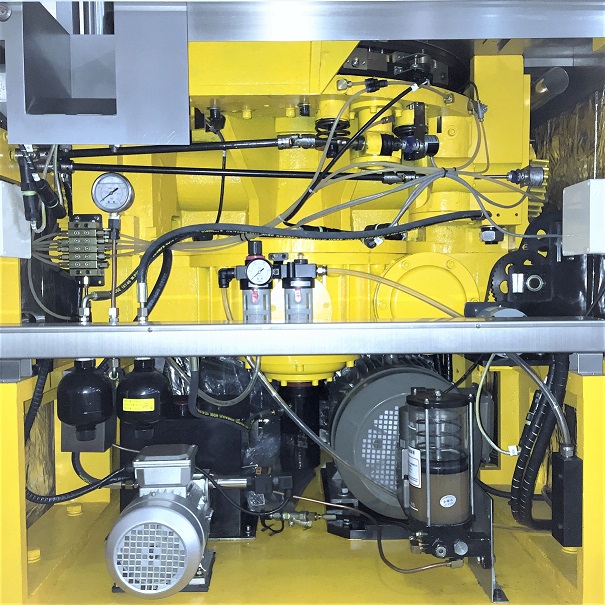

4. This is the image of the lower cabinet under the turret of the smart rotary tablet press. Grease oil lubrication pump help to make sure that the grease oil can be lubricated smoothly and easily, which is very important for the automatic pill making machine's maintainance.

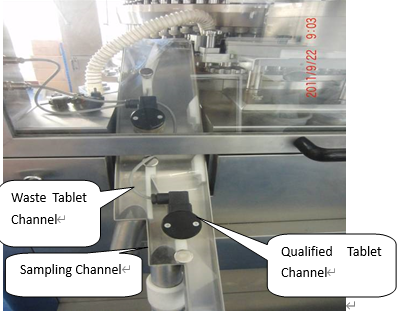

5. Defective tablets rejection system is equipted on this rotary pill press machine, and the sustandard tablets can be rejected through the waste tablet chute automatically.

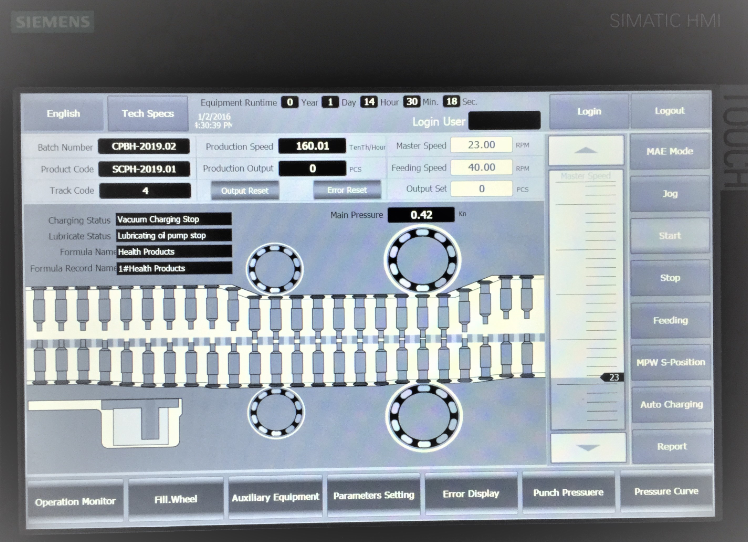

6. Touch screen on this automatic tablet compressing machine make the operation very easy and convinient. You can read and adjust the pre-pressure, main-pressure, speed, and filling quantity, tablet thickness on the touch screen. All the data can be stocked and taken out with flash memory card.

Main Technical Data

Model No. | GZPK720I-51 | GZPK720I-65 | GZPK720I-83 |

Quantity of Punch & Die (set) | 51 | 65 | 83 |

Tooling Type | D | B | BB |

Max. Main-pressure (kn) | 100 | ||

Max. Pre-Pressure (kn) | 16 | ||

Max. Dia. of Tablet (mm) | 25 | 16 | 13 |

Max. length of Irregular tablet(mm) | 25 | 19 | 16 |

Max. Depth of Filling (mm) | 20 | 20 | 16 |

Dia. of Middle Die (mm) | 38.1 | 30.16 | 24 |

Punch Diameter (mm) | 25.35 | 19 | 16 |

Rotation Speed (r/min) | 8-80rpm | ||

Production Capacity (pcs/h) | 61200-612000 | 62400-624000 | 79600-796000 |

Motor Power (kw) | 11 | ||

Overall Size (mm) | 1294*1500*2000 | ||

Dimension of control cabinet | 890*500*1200 | ||

Weight (kg) | 5500 | ||