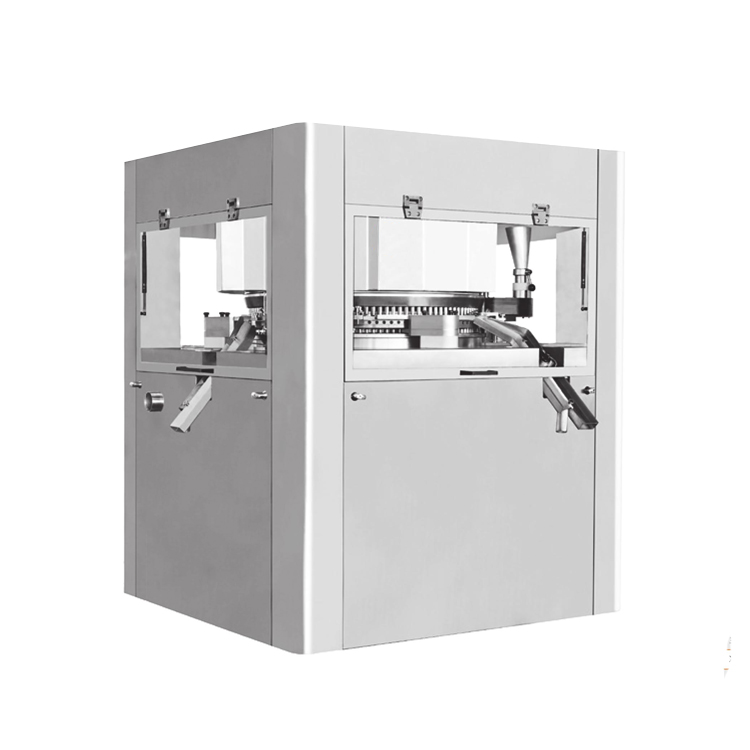

automatic medicine pill making machine

- TP

- China

- 35 days

GZP540 high speed rotary tablet press machine has two discharges, and can press 350000pcs/hour, main pressure of the automatic high-speed tablet making machine is 100KN, and pre-pressue is 30KN.

The thickness, filling quantity can be displayed on the PLC interface.

Thin oil lubrication system is adopted on this high-speed rotary tablet press machine, and the lubrication is very accurate and the lubrication quantity can be set according to requirement.

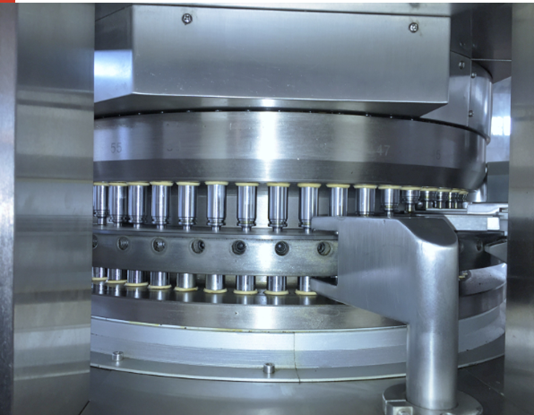

The force feeding system can be removed and installed very easily. This rotary tablet press machine has two groups of tablet pressing wheels, and is very suitble for checmical, food and electronic products production.

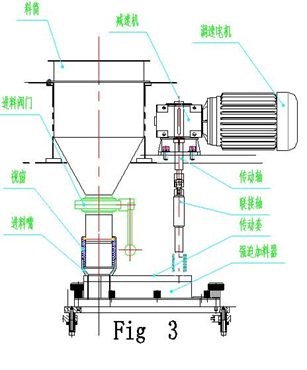

Full closed force feeder diagram of this high-speed rotary tablet press is as below:

Full closed force feeder on this automatic rotary tablet making machine can be taken out and put back very easily, and this force feeder help to make the powder filling very smooth and accurate. The blades inside the force feeder are processed from a complete steel pannel on wire cutting machine, rather than on welding machine.

Dust collector nozzle is connected with a vacuum dust collector, and the extra powder on the rotating plate of the Tablet Press Machine can be absorbed effectively.

Automatic pill press machines hand wheels are seperately for Main pressure,pre-pressure, material filling, Main pressure, pre-pressure,and material filling.

Discharge chute on the catalyst tablet press machine is as below(if press two layers of tablets, there will be only 1 chute), it is suitable for the factory which plans to replace normal speed rotary pill press machines with high-speed rotary tablet press machine.It is very cost effective.

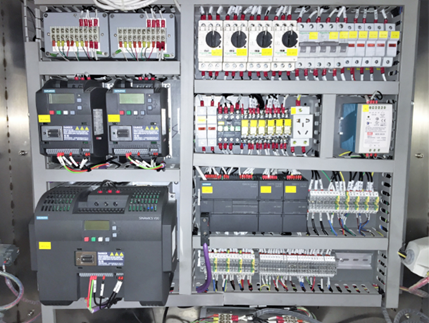

below is the image of the electric cabinet of the pharmaceutical tablet press machine. Famous brand electric devices are adopted on this pill compressing machine.

Main Technical Data

Product No. | GZP540-39 | GZP540-47 | GZP540-57 | GZP540-61 |

Quantity of Punch & Die (set) | 39 | 47 | 57 | 61 |

Tooling Type | D | B | BB | BBS |

Main Pre-pressure (kn) | 30 | |||

Max. Pressure (kn) | 100 | |||

Max. Dia. of Tablet (mm) | 25 | 18 | 14 | 11 |

Max. Thickness of Tablet (mm) | 8 | 8 | 8 | 8 |

Max. Depth of Filling (mm) | 20 | |||

Rotation Speed (r/min) | 5-48 | |||

Production Capacity (pcs/h) | 22464-112320 (two layers) | 27072-270720 | 32032-320320 | 35136-351360 |

Voltage (v/hz) | 380/50 | |||

Motor Power (kw) | 7.5 | |||

Lubrication | Automatic | |||

Overload protection | Yes | |||

PLC | Pressure, filling depth, thickness, speed, | |||

Outside Size (mm) | 1300×1100×2160 | |||

Weight (kg) | 3000 | |||

Actual speed depends on the material characteristics and the tablet shape & size.