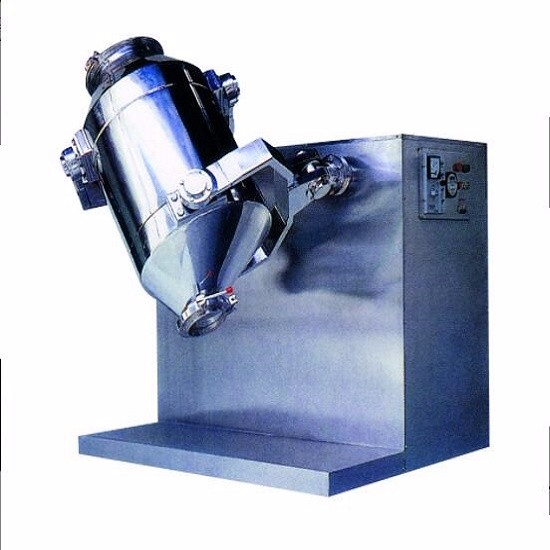

Pharmaceutical Trough Type Mixer

As a whole stainless trough type mixer, this pharmaceutical powder blender is widely used for mixing of powdery or paste material in pharmaceutical chemical and foodstuff industries.

This machine is single bearing tank type mixer. This groove shape mixer is used to mix material in pharmaceutical industry. This trough type mixer can mix dry power, wet power and paste material in proportion uniformly, during operation, the material will not dissolve, volatilize or deteriorate.

Main technical data of this pharmaceutical powder blender

ITEM | TYPE | ||||

CH10(A) | CH50(A) | CH100(A) | CH150(A) | CH200(A) | |

Trough capacity L | 10 | 50 | 100 | 150 | 200 |

Miaing arm speed r/min | 25 | 24 | 24 | 24 | 24 |

tilting angle of the trough | 110 | 110 | 105 | 105 | 105 |

Main motor KW | 0.37 | 1.1 | 1.5 | 3 | 4 |

tilting motor KW | by hand | ||||

overall dimension mm | 610*250*480 | 1200*520*1000 | 1380*685*1125 | 1580*685*1125 | 1840*600*1050 |

weight kg | 65 | 200 | 250 | 350 | 450 |

Principle and structure of this pharmaceutical powder mixing machine

This tank type mixer machine is driven mechanically, with the main axletree rotate in the tank. There is an S-shape airscrew in the main axletree, which will push the material flow in a perplexing way, repeat this operation some times will get a good mixing result.

Some characters of this tank type mixer:

1)The tank, airscrew, and other parts which will contact the material are all made of 1Cr18Ni6Ti stainless steel which is anti-acid and anti- alkali.

2)There are sealed cleaning equipments at the two ends of the airscrew, which will prevent the material from leaking, and at the same time, it will prevent other material from getting into the tank.

3)The airscrew is S-Shaped, thus it will mix the material in big amount efficiently.

4)CH-50,CH-100,CH-150 and CH-200 have automatic dump equipment, it will dump the material which is mixed into other tank, and it is easy to clean the tank and the airscrew. CH-10 can be operated to dump material manually, it is safe and convenient.

5)The Trough type mixer is driven by worm wheel, which will help the machine to work placidly

4.Lubrication for this Groove shape Mixer

1)This groove shape mixer machine use worm wheel deceleration machine, which has good performance. Before using it, this powder mixer must be infused N46 machine oil, at first ,change the oil every two weeks, half year later, this trough type mixer must be cleaned and change the oil, in order to prevent the feculence from getting into the tank, thus effect the life of this machine, it is prohibited to operate without oil.

2)The inner bearing of the tank must be infused ZG-3H lubricating oil.

5. Installation and debugging for this Pharmaceutical Trough Type Mixer

1)The tank type mixing machine must be installed placidly and fixed with bolts

2)Screw off the oil bolts; infuse the lubricating oil into deceleration machine till the mark line.

3)During debugging ,The Trough type mixer machine must be checked carefully, in order to see if there are any fasteners are loosen, if there is any abnormal noise. When needed, stop the powder mixer and check.

6. Operation procedure for this tank shape mixing machine

1)Check the fasteners of this trough type mixer to see if they are loosen before operation.

2)Clean the tank and the airscrew of this pharmaceutical mixing machine.

3)Operate the power, make the airscrew work for 5 minutes, if it is ok, then add the material .

4)For CH-10, please be sure that the lock screw is not loosen, or the tank will incline.

7. Maintenance and safety notice for this trough type mixer

1) change the lubricating oil in the deceleration machine and the roll bearing periodically.

2) In order to make sure that the lubricating condition of the worm wheel in the deceleration box is good, the temperature during operation must be below 35°C

3)The tank type mixing machine must be grounded reliably, the resistance must be ≤ 4Ω

4)The electric equipment and the safety cover of the belt can not be dismantled optionally.