Pharmaceutical Pulverizer

- TP

- Shanghai,China

- 20-25 days

- 30 units per month

Pharmaceutical Pulverizer is suitable for pharmaceutical, chemical, pesticide, food and grain industries, and has a wide range of uses.

Pharmaceutical Pulverizer uses the high-speed relative movement between the movable toothed disc and the fixed toothed disc to crush the object to be crushed through the combined effects of tooth impact, friction, and impact between materials.

The structure of this pulverizer machine is simple, sturdy, well-balanced, and has good crushing effect. The crushed material can be directly discharged from the grinding chamber of the powder pulverizer .

The other 30B type ultrafine pulverizer machine is all stainless steel. All the inner walls of the casing are machined to achieve a smooth and smooth surface, which enables the production of pharmaceuticals, food, chemicals and other products to meet national standards and meet GMP requirements.

Main Technical Data of the pulverizer machine

Product No. | GF-20B | GF-30B |

Production Capacity (kg/h) | 30-50 | 50-100 |

Spindle (r/min) | 4500 | 3800 |

Fineness (mesh) | 20-120 | 80-120 |

Feeding Size (mm) | <10 | <10 |

Motor Power (kw) | 4 | 5.5 |

Overall Size (mm) | 1100*650*1600 | 1120*450*1400 |

Weight (kg) | 300 | 450 |

Superfine pulverizer is suitable for crushing brittle materials in the pharmaceutical, chemical, food, pesticide and other industries. lab pulverizer is a new generation of crushing equipment that integrates crushing and vacuuming. this pulverizer grinding machine has a wide range of uses.

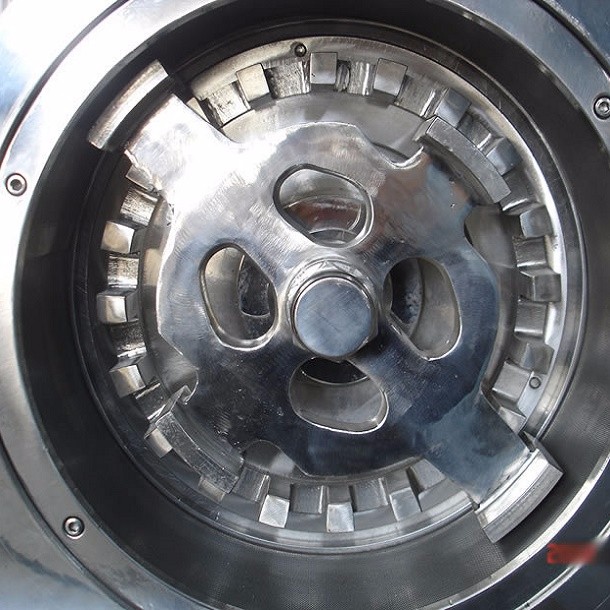

inside image of the pulverizer machine

Superfine pulverizer is composed of a pulverizer, an ESC material collection box and an ESC vacuum cleaner, which solves the problem of flying dust during the pulverization process.

This unit Pharmaceutical Pulverizer makes use of the relative movement between the movable gear and the fixed gear, so that the materials are crushed by the impact and friction of the teeth and the materials. The crushed material automatically enters the predator bag by the effect of rotating centrifugal force, and the dust is filtered and recovered by the dust collection box through the cloth bag.

Superfine pulverizer is designed according to the "GMP" standard and is made entirely of stainless steel. No dust is flying during the production process.This quality pulverizer can improve the utilization rate of materials and reduce the cost of the enterprise. At present, this pulverizer machine has reached the international advanced water level.

Working principle:

Pharmaceutical Pulverizer has a horizontal crushing structure. The material enters the crushing chamber from the feeding hopper, and is crushed by the impact and shear of the rotary knife and the fixed knife. After the action of the rotary centrifugal force, the material automatically flows to the outlet. The pulverizer is designed according to the "GMP" standard. The whole pulverizer machine is made of stainless steel, with a simple structure, convenient cleaning and low noise. This pulverizer machine is currently an ideal equipment for coarse crushing.