Industrial Tablet Press

- TP

- Shanghai,China

- 20-25 days

- 200sets/month

Features:· This Graphite tablet press has sufficient pressure and good forming effect.· The outer cover of this PTFE Gasket press is fully enclosed. The material is stainless steel, and the internal die table of this industrial tablet press is made of stainless steel.

The surface of the dietable on this button battery press is specially treated to maintain surface gloss and prevent cross-contamination, which meets GMP requirements.·

Transparent acrylic doors and windows, can clearly observe the state of the tableting, and can be fully opened, easy to clean and maintain internally.All controllers and operations on this shisha charcoal tablet press are reasonably laid out.· Adopts frequency conversion speed regulating device for electrical speed regulation, convenient operation, stable rotation, safe and accurate.·

All transmissions on are arranged inside the Graphite tablet press to keep the parts clean.·

this type of PTFE Gasket press is equipped with overload protection device, this shisha charcoal tablet press can automatically stop when pressure is overloaded.· The industrial tablet press is equipped with an electromagnetic brake motor and other safety protection devices, which can also be adjusted and operated during operation.

Graphite tablet press with PLC touch screen

This Graphite tablet press is a double-press automatic rotating, continuous tablet press that compresses granular raw materials into different tablets. This PTFE Gasket press is designed and manufactured for industrial tablets. Can be used in the plastic chemical industry, such as tabletting of polyurethane particles, but also suitable for chemical, food, electronics and other industries.

Main Features of this PTFE Gasket press

1. This shisha charcoal tablet press machine(button battery press) is especially suitable for tablets with large diameter and large filling volume.

2. Specially designed compulsory feeder can make pure powder materials with light weight and small density.

3.Specially designed auxiliary equipment for this button battery press can realize automatic feeding and automatic film output.

4. Humanized design for this Graphite tablet press makes the machine easier to clean and maintain.

5. The transmission system of this industrial tablet press is enclosed in a worm gear box below the main body and is a completely separated independent component, which will not contaminate each other, but also fully lubricate the transmission pair, reducing noise and wearing.

6. The special installation structure makes the replacement and maintenance of the lower rail guide and the lower roller easier and faster.

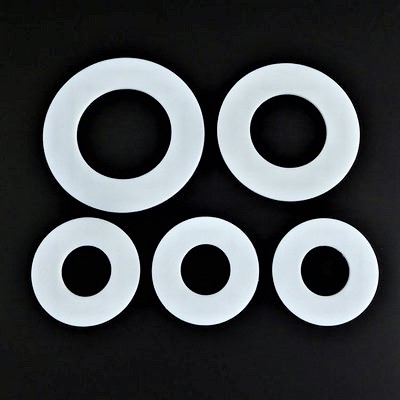

These are the PTFE Gasket samples pressed on this PTFE Gasket press machine.

Structure and composition

Graphite tablet press that puts granules or Graphite particle material into the die holes and presses them into tablets is called a Graphite tablet press.

The earliest tablet press consisted of a pair of punches. The punches moved up and down to compress the granular materials into tablets. This machine was called a single punch tablet machine and later developed into an electric basket press. The working principle of these two types of tablet presses is still based on the manual compression die-based one-way tabletting, that is, the down punch is fixed and the press is only pressurized.

Due to the inconsistent upper and lower forces in this tabletting method, the density inside the tablet is uneven, and problems such as chipping are easy to occur.

Aiming at this shortcoming of unidirectional tablet press, a rotary multi-punch bidirectional tablet press began to be produced. This tablet press' punches go up and down at the same time and uniformly pressurizes, so that the air in the drug particles has ample time to escape from the die hole, which improves the uniformity of the tablet density and reduces the phenomenon of chipping. In addition, the rotary tablet press has the advantages of small machine vibration, low noise, low energy consumption, high efficiency, and accurate tablet weight.

Rotary tablet press is a machine that uses a plurality of punches evenly distributed on the turntable to make a circular lifting movement according to a certain trajectory, and presses the granular material into a tablet through a pressing wheel. A tablet press with a linear speed of ≥60m / min when the punch rotates with the turntable is called a high-speed rotary tablet press. This high-speed rotary tablet press has a forced feeding mechanism. The machine is controlled by a PLC and has automatic pressure adjustment and control. Film weight, rejection of waste film, print data, display failure shutdown and other functions. In addition to controlling the difference in film weight within a certain range, it can automatically identify and eliminate quality problems such as missing corners and loose chips.

The tablet shape pressed by the tablet press was mostly oblate at first, and later developed into shallow circular and deep circular shapes on the upper and lower sides. This is for coating needs. With the development of special-shaped tablet presses, oval, triangular, oblong, square, diamond, and circular tablets have been produced. In addition, with the continuous development of preparations, due to the requirements of compound preparations and timed release preparations, special tablets such as double-layer, triple-layer, and core-covering are made, which must be completed on a special tablet press.