Capsule Polishing Machine

This capsule polishing machine is desgined for polishing capsule, and and make the capsule very smooth and nice looking. This capsule polisher can easily get rid of the residue powder from the surface of the capsule very fast.

We are able to manufacture around 60 sets of capusle polishing machine every month, and most of these capsule deduster are exported worldwide through our distributors or tading companies.

Welcome to visit our factory in Shanghai, around 1 hour's drive from Pudong international air port.

Points for Attention of Operation for this capsule polisher:

1.Before switching on power for this capsule polishing machine, turn the main shaft of the motor by hand, and make sure that there should be no phenomenon of seizing-up.

2.Check and make sure that every fastener on this capsule deduster should be tightened.

3.Insert the power plug of the dust collector into the socket of under the capsule polisher machine body, connect the dust exhaust hose and regulate the voltage regulator to 200V or so. After the dust collector starts working, turn on the power switch and pour in a little medicine, regulate the voltage and change the rotational speed until the surface cleaners of the medicine has a satisfactory effect. The rotational speed is inversely proportional to the cleanness.

4.In order to retrieve surplus medicinal power, we suggest that the medicine should be screened once with the griddle before being polished by this capsule polishing machine.

5.Both adding a little starch to the hairbrush and binding the material outlet with a towel can improve the surface cleanness of medicine.

6.Before the hairbrush and the mesh cloth will heat through friction during operation, the surface cleanness of the capsule polishing medicine will be affected by superheat. So the operator should grasp the operating method and make sure that continuously running time of the machine shouldn’t be too long.

7.Wash the hairbrush, mesh cloth and material cylinder before polishing different kind of meidicne with this capsule polisher.

8.The stand-by hairbrush should be hung and not be placed horizontally after it is washed.

9.The filter bag of dust collector should cleared up after the capsule polisher stops working.

II Washing, Assembling and Disassembling of Hairbrush:

1.Loosen the fixing screws on the front and rear bearing covers, remove the bearing cover (1) and take down the upper half part of the polishing cylinder (2)

2.Loosen the fixing screws of the shaft coupling on the side of the hairbrush so as to separate the hairbrush from the shaft coupling of the motor.

3.Take out the hairbrush, mesh cloth and spring (3) together, and then pull the mesh cloth open and take out the hairbrush, wash it and then dry it in the air.

4.When washing the hairbrush, you needn’t remove the bearings on both ends of the hairbrush but should keep the bearings rustless and make sure that there is no phenomenon of seizing-up.

5.After assembly, the hairbrush of this capsule polisher should be connected with the shaft coupling of the motor. Turn it by hand and check to make sure that there should be no phenomenon of seizing-up.

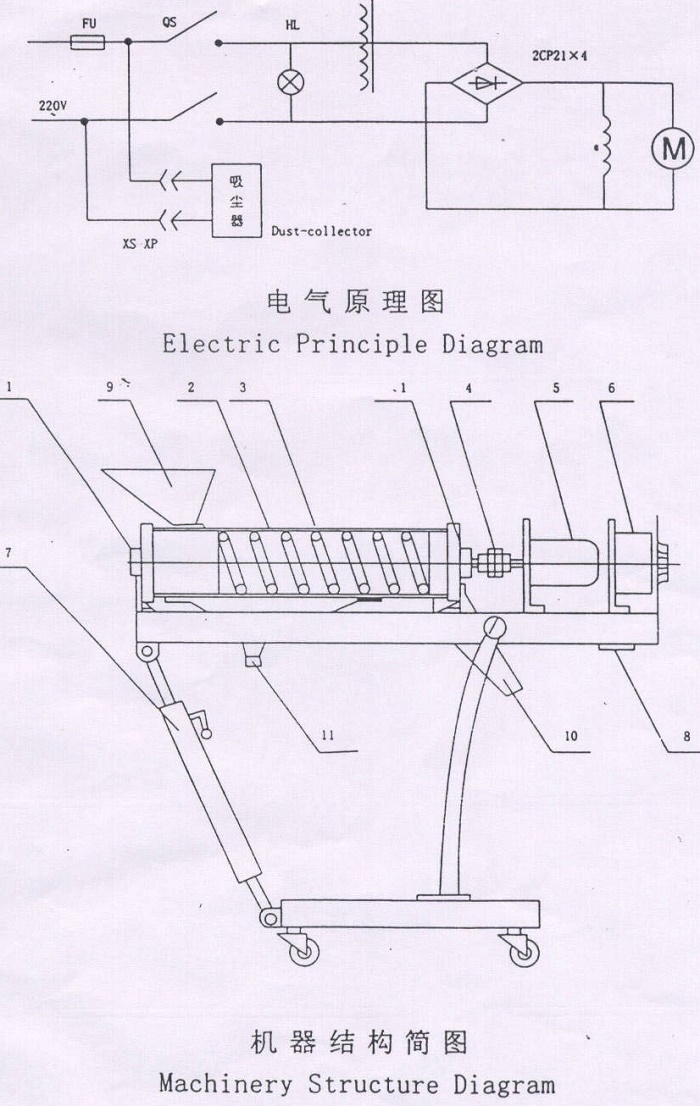

III Electrical Schematic Diagram: (Attached)

IV Structural Diagram of Machine: (Attached)

1.Bearing Cover

2.Organic Class Cylinder

3.Mesh Cloth, Spring, Hairbrush

4.Shaft Coupling

5.D.C.Motor

6.Speed Regulator

7.Height Adjustment Rack

8.Socket of Dust Collector

9.Material Inlet

10.Material Outlet

11.Dust Inlet